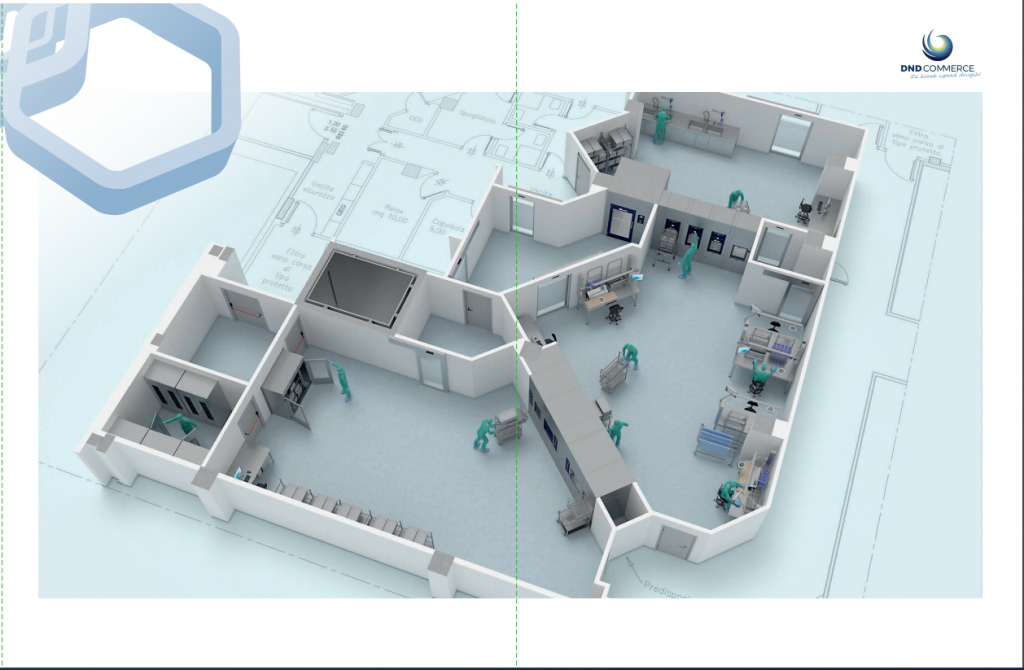

Contaminated area

Contaminated instruments should be free from blood and tissue residues. The best solution for safe removal of all residues is pre-wash in Steelco ultrasonic units. An impeccable way to clean lumen and heavily soiled instruments is with high frequency. Instruments soaked in water and detergent are rinsed by sending ultrasonic waves produced by an electronic generator. With the cavitation bubbles provide an easy access to cracks, holes, perforations to be cleaned.

After pre-wash process, wash cycle should be performed, so as to send the instruments forward to the clean area for further sterilization process. Wash cycle is performed at 93 °C in order to destroy bacteria. The solution for contaminated area is a sterilization unit, Steelco washer disinfector.

Clean area

After the instruments have cooled, they are assambled in CBM wire baskets according to the protocol, with the cellulose paper at the bottom for absorbing exces condensate as well as to protect sharp instrument tips from being damaged (protruding of thinner instruments from the grid). class V steam integrator by Amcor is also placed in the basket, as a relevant sterilization control. What follows is wrapping inside Sterisheet duo paper, by Sterimed. Another packaging option is: Ultra and Bop reels. Also, instruments placed in CBM baskets could be wrapped in INTEGRApak. One4All is also designed for easy packing in INTEGRApak, green and blue SMS paper.

Sterile area

We have come to sterile area of SSD with double-door Steelco sterilizers. Front door is facing clean sterilization area for packaging and setting the cycle. In sterile area the door is authomatically opened upon finishing of the cycle, and the instruments and other objects are easily removed with the help of a trolley.

In addition to Printex labels for marking the date of completed sterilization cycles, each step carried out in all of the three areas must be entered, for keeping a record of sterilization unit.